Signifikant for

Circular Economy

The DiCiM Project

The DiCiM project is dedicated to demonstrating a comprehensive set of digital solutions that empower various stakeholders within the industrial value chain. These solutions facilitate value recovery activities, pivotal to advancing a circular economy. The central mission is to increase the return and remanufacturing of spare parts and appliances, thereby minimizing waste and promoting sustainable practices.

How Signifikant Drives Digital Transformation for Circular Value Chains

Signifikant, as part of the DiCiM project, provides a comprehensive digital framework that empowers organisations to manage and optimise the entire product lifecycle. By combining data from multiple sources, including IoT sensors, ERP systems, and machine histories, the platform enables informed decisions on maintenance, repair, and remanufacturing.

These capabilities increase the return of spare parts and appliances, reduce waste, and support more sustainable business practices. Want to explore how digital circular solutions can help your organisation?

Signifikant's Open Access Digital Platform (OAD

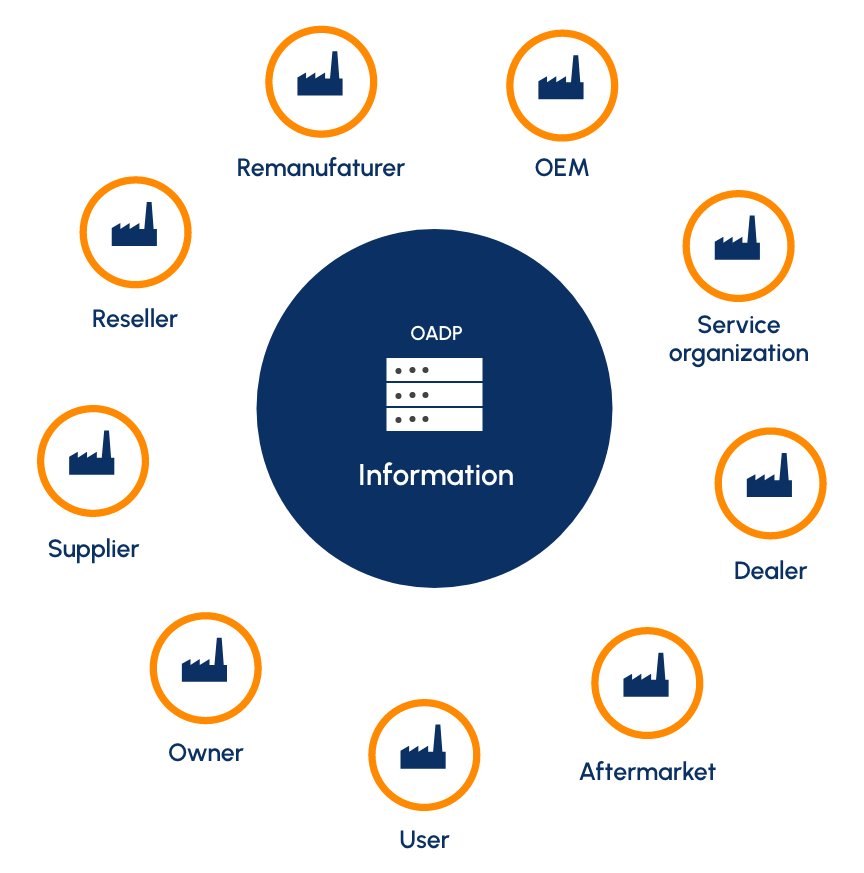

Being a central piece of the integrated digital solutions, Signifikant’s OADP supports organisation and systems involved in the reverse lifecycle processes to share information in order to increase the number of returned and remanufactured spare parts and appliances.

Functionality

The Signifikant OAD Platform is an open-access platform with the purpose of solving general data sharing, management, and publication issues for multiple organizations that cooperate in value recovery processes. The main functionality for the platform is:

- Import and unification of information used by the value recovery processes

- Enrichment and publication of the information to multiple channels

- Consumption of the information through the OADP portal, files or API

- Integration with systems that provide functionality to the value recovery processes

Companies can join the OADP on two levels:

- Customer companies will only consume information

- Participant companies will both share and consume information

- They can control on a very granular level which companies and roles will have access to what data.

Key Benefits of the Open Access Digital Platform

Signifikant’s Open Access Digital Platform offers a range of benefits for organisations engaged in value recovery and circular economy initiatives:

- Efficient Data Sharing: Seamlessly share and access accurate product and component information across multiple stakeholders.

- Improved Decision-Making: Real-time insights into product condition and lifecycle enable smarter repair, reuse, and remanufacturing decisions.

- Enhanced Traceability and Transparency: Track the history and status of parts to reduce errors, waste, and downtime.

- Maximised Value Recovery: Optimise the reuse and remanufacturing of spare parts and appliances, supporting sustainable practices.

- Scalable Collaboration: Organisations of all sizes can participate, control access, and adapt processes to their specific needs.

- Support for Circular Business Models: Data-driven insights enable companies to implement effective circular economy strategies.

Industries That Can Leverage the Open Access Digital Platform

Signifikant’s Open Access Digital Platform is adaptable across a wide range of industries where spare parts and lifecycle management are critical. This includes

- Manufacturing and heavy machinery

- Electronics and consumer appliances

- Automotive and transport, and energy

- Industrial equipment

By providing structured, shareable, and accessible data, the platform enables each sector to implement circular economy practices, optimise value recovery, and improve sustainability across their operations.

Why Data Sharing Is Essential for a Circular Economy

Accurate and timely data is the backbone of a functioning circular economy. Signifikant’s platform enables organisations to share and access critical product and component information across the entire value chain, from manufacturers to remanufacturers and service providers.

This shared data supports traceability, predictive maintenance, and informed decisions on repair, reuse, and remanufacturing, which maximise value recovery and minimise waste. By promoting secure and controlled data exchange, the platform also enables new circular business models, optimises resource use, and reduces environmental impact. Ultimately, effective data sharing allows companies to implement practical, measurable circular economy strategies that benefit both the business and the planet.

Use Cases

Expose Demand for used components in service portal

The Signifikant OADP will integrate with C-ECO’s platform to inform a service technician or customer that orders a spare component in case there is an interest (option) for the replaced component. A return for the used component can be ordered together with an order for the spare component.

Expose Demand for used appliances in customer portal

The Signifikant OADP will integrate with Lexmarks Collected By Lexmark (CBL) portal to show the takeback/buyback price for a list of printers. The price will be based on a machine learning model that takes into account the remanufacture level of the printers.

Inventory of returned appliances to enable reuse of parts

The Signifikant OADP will integrate with Arçeliks warehouse applications to keep an inventory of returned appliances and the parts they contain. The collectable spare parts will be searchable and if removed, this will also be captured.

Standard product data format for reverse lifecycle processes

A standard API for sharing product information will be created that supports the needs of the reverse lifecycle processes. Data will be imported from C-ECO (products and BOMs), Lexmark (products), Arçelik (products and BOMs), Gorenje (IoT and ML results) to the Signifikant OADP.

Try The DiCiM Project Yourself

A demonstration site, which includes some publicly available data, will be made available and continuously improved during the course of the DiCiM project.

Funded by the European Union

Key Terms Explained

- Circular Economy: A system that aims to minimise waste and make the most of resources by reusing, repairing, refurbishing, and recycling products throughout their lifecycle.

- Value Recovery: The process of reclaiming usable parts, materials, or products from returned or end-of-life items to maximise economic and environmental value.

- Remanufacturing: Restoring used products or components to like-new condition, extending their lifespan, and reducing the need for new raw materials.

- Reverse Lifecycle Processes: Activities that track, collect, inspect, repair, and redistribute products or parts from the end of their first life back into the supply chain.

- Open Access Digital Platform (OADP): Signifikant’s platform that enables multiple stakeholders to share, access, and manage product and component data securely across the value chain.

- Predictive Analytics: Using data and machine learning to forecast maintenance needs, part failures, and optimal timing for repair or remanufacturing.

- Traceability: The ability to track products and components throughout their lifecycle, providing visibility into condition, usage, and history.